- Epitixial Wafer Growth

- Wafer Fabrication

- Chip Packaging

- Chip Testing

Utilizes advanced MOCVD systems to produce epitaxial wafers for laser light source chips, offering foundry and customized growth services for 2- 6 inch wafers.

Capable of independently growing GaAs- and InP-based materials and epitaxial structures for edge-emitting and VCSEL devices.

Capable of characterizing epitaxial structures, including wavelength, composition, and doping profiles.

-

Photolithography/Etching

Photolithography: UV lithography, nano-imprint lithography

Etching: Dry etching, wet etching

-

Thin-Film Deposition

Insulating Films: SiO₂, Si₃N₄, Al₂O₃, HfO₂

Metal Films: Ti, Pt, Au, AuGe, Ni, Ge, Cr, etc.

Deposition Techniques: Evaporation, sputtering, electroplating

-

Ion Implantation

Wafer Sizes: 4-inch, 6-inch, and small pieces

Energy Range: 30–380 keV (single charge)

Implant Species: H⁺, He⁺

-

Wafer Dicing & Facet Coating

Coating Materials: SiO₂, Al₂O₃, Ta₂O₅, Nb₂O₅, Ti₃O₅, Si

Reflectance Range: 0.1%–99%

-

Thinning & Polishing

GaAs and InP substrates

-

Wet Thermal Oxidation

Process: Al(Ga)As wet N₂ oxidation

Wafer Sizes: 4-inch, 6-inch, and small pieces

We offers a wide spectrum of customizable packaging solutions—including TO, COC, COS, C-Mount, CS, and F-Mount packages, as well as fiber-coupled modules—precisely tailored to the specific requirements of diverse applications.

-

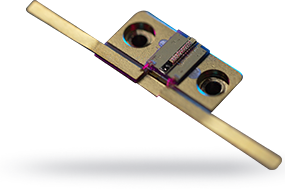

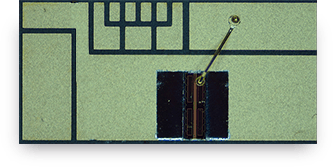

COS Module

-

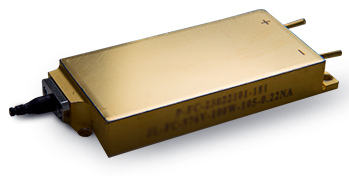

F-MOUNT Module

-

Fiber Coupled Module

-

Fiber Coupled Diode Laser

System

-

COC Module

-

1

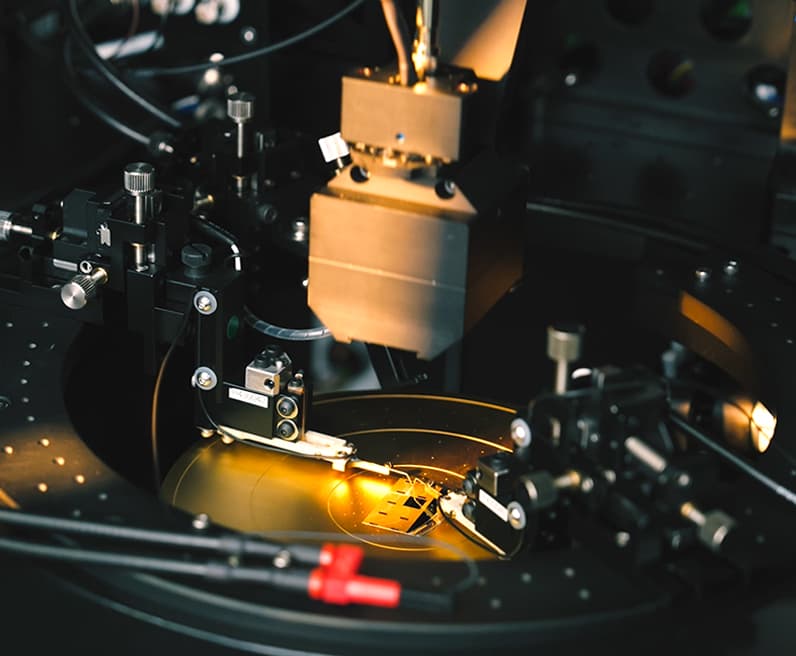

Automated Chip Testing

Automated Probing & Sorting for 4-6 inch VCSEL Wafers

-

2

High-Frequency Device Testing

Small-signal Characterization

Large-signal Characterization

RIN (Relative Intensity Noise) Measurement -

3

Reliability Testing

Real-time Aging Monitoring

Temperature Cycling From –40 °C to 85 °C

High-temperature, High-humidity Test (85°C/85 % RH)

Search

Search

中文

中文